Adaptive alignment features when working in dangerous areas

ATEX/IECEx Zone 1 certified including ruggedized IP68 tablet device

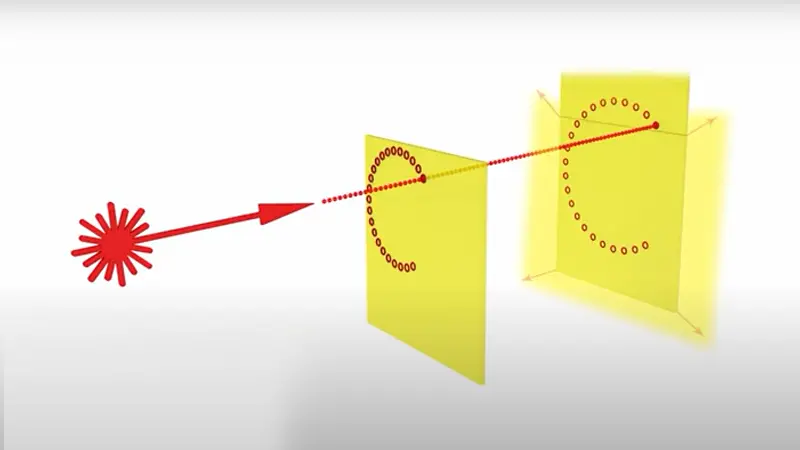

Single-laser technology sensALIGN 5 featuring SWEEP and PASS Mode for uncoupled shafts

Active Situational Intellgence

Simultaneous Horizontal and Vertical Live Move + Move Simulator

Thermal growth and targets

Spacer coupling and in-situ Cardan shaft alignment with rotating arm bracket

Soft Foot Wizard to diagnose soft foot problems

6-machine train alignment

Advanced vertical machine alignment with vertiSWEEP continuous measurement mode

ALIGNMENT RELIABILITY CENTER 4.0 PC software including auto-activation and PDF reporting

Mobile connectivity with integrated Wi-Fi, Bluetooth, RFID and camera

Interested?

Find out more …

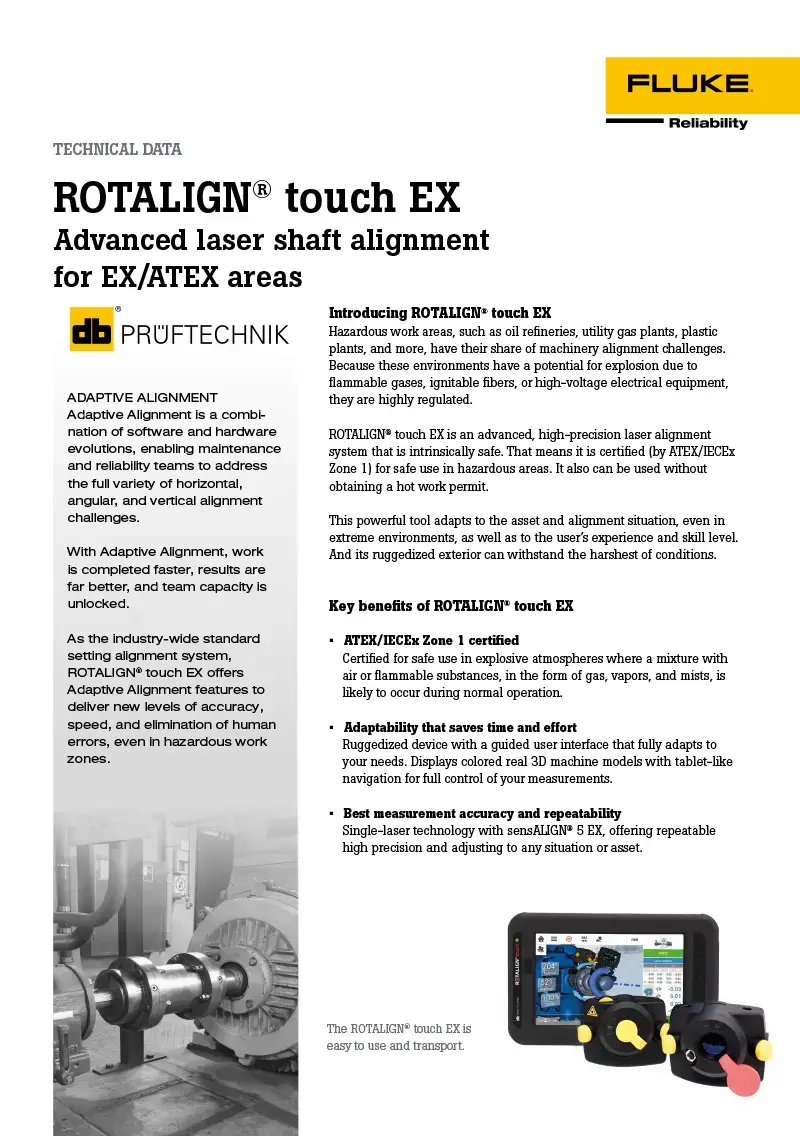

Advanced laser shaft alignment in EX/ATEX areas

ROTALIGN touch EX is Zone 1 ATEX/IECEX certified. Packed with user-friendly alignment features unique to PRUFTECHNIK, the ROTALIGN touch EX shortens the measurement time with:

Continuous SWEEP Mode for high-quality measurement in only one shaft rotation

Live Move function for simultaneous real-time machine corrections in both horizontal and vertical directions

vertiSWEEP to measure vertical machines in one rotation of the shaft

Cardan shaft rotating-arm bracket allows measurements to be performed without removing the shaft

Soft Foot Wizard to diagnose soft foot problems

Move Simulator lets the operator simulate shim values and horizontal corrections before moving the machine

Have instant access to the critical data you need with full mobile connectivity. The ROTALIGN touch EX tablet is Wi-Fi enabled and equipped with a Bluetooth module, an integrated camera, and an RFID reader for automatic machine identification and error-free two-way transfer of asset data.

Direct communication between the tablet and the ALIGNMENT RELIABILITY CENTER 4.0 PC software allows specialists to archive, analyze, and process alignment data to improve asset performance improvement and reliability.

sensALIGN 5

sensALIGN Series technology is based on PRUFTECHNIK single-laser technology and provides highly precise measurement results with the easiest mounting and measuring in the field.

sensALIGN 5 sensors include two HD large position-sensitive detectors (PSD) and MEMS inclinometers. Combined with detector extension capability (InfiniRange), it is always possible to measure and document the initial alignment condition, no matter how big the misalignment.

The technology also allows the simultaneous monitoring of machine corrections in vertical and horizontal directions, starting from any angular position where the sensor comes to stop.

Download more information for free

Brochure

Technical Data

Manuals

Customer FAQ

What's new?

touch device Firmware Version 2.5.1

ANSI tolerances available for Short flex and Spacer coupling types

Resolution available in both 2DP and 3DP (Metric)

Report print preview

Report new section: Measurement equipment serial number and due calibration date

Tolerance screen accessible directly from Results view

Context sensitive help ‘?’ button directly accessible within main workflow screens

"Add feet" button available in stationary machine properties

Please note: touch device firmware version 2.5.1 strictly requires ARC 4.0 software version 2.5 to communicate.

How to upgrade your firmware?

ROTALIGN touch EX device - updating procedure

Download and unzip the “rom” files on a PC

Please ensure the ROTALIGN touch EX device is charged or has at least 50% battery capacity

Switch on the ROTALIGN touch EX device and connect it to the PC. A hint to allow the Windows PC access to the device appears

On confirmation, the ROTALIGN touch EX device shows up on the File Explorer

Double-click “Tablet” to access folders on the ROTALIGN touch EX device

Transfer all unzipped “rom” files to the ROTALIGN touch EX device folder “FirmwareUpdate”

After all the “rom” files have been copied to the “FirmwareUpdate” folder, disconnect the ROTALIGN touch EX device from the PC

An on-screen message box “Firmware update in progress. Please wait” appears on the ROTALIGN touch EX device

Wait for the subsequent on-screen message box “Update available proceed with update” to appear.

Tap green tick button to proceed with the firmware update

Follow all the update instructions carefully, and confirm all requested installations

Once the firmware is completed, a hint to restart the ROTALIGN touch EX device appears

Press and hold down the power key briefly. “Power off” and “Restart” icons appear on the display

Tap “Restart”. The update is now completed and after restart may be checked and confirmed in the “About” menu item in configuration

Device Viewer

The Device Viewer software is used to demonstrate the operation of the instrument on a PC or Laptop.

Fluke Deutschland GmbH

Fluke Deutschland GmbH