Geometrical Measurement Software

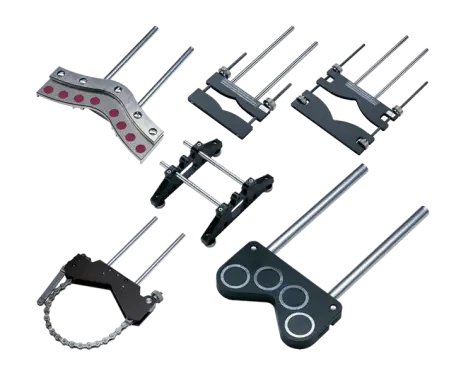

Activate your machinery more quickly, and help it run longer. PRÜFTECHNIK geometric laser alignment tools and software enable you to easily check and adjust your machine geometries for: straightness, flatness, level, inclination, plumbness, parallelism, and right angle check. Our tools are powerful, precise, and easy to use on a vast range of machinery—they can measure for the most demanding alignment jobs, including a bore of almost any diameter, and/or any surface type or inclination. Find the right geometric measurement tool for your machines.

Frequently Asked Questions

Geometric measure theory (GMT) studies the geometric properties of sets through what mathematicians call measure theory. GMT lets mathematicians expand the tools provided by differential geometry to cover a much larger class of surfaces, including inclination, straightness, level, and flatness.

What are the Benefits of Using a Geometric Tool?

Geometric tools measure surface flatness, foundation levelness, straightness and parallelism, machine geometrics, and shaft plumbness.

Geometric measurement technology covers many tools, from simple straightness to complex right-angle measurements needed when moving machinery or installing large machines like turbines or rolls.

Today's more sophisticated geometric measurement systems use laser technology, enabling faster and more efficient measurements of flatness of surfaces, level, and perpendicularity. Precision laser shaft alignment tools produce a flat plane of laser light that can be maneuvered to fit multiple needs and used to test equipment and machines as a point of reference.

In addition to geometric laser alignment tools, geometric software lets reliability professionals measure straightness, flatness, level, inclination, right angle, plumbness, and parallelism and view the results in 3D.

The Benefits of Geometric Tools

Geometric tools, such as laser shaft alignment systems, allow users to take critical measurements, including machine geometrics, shaft plumbness, surface flatness, foundation levelness, straightness, and parallelism

What Geometric Tools Can Help with Geometric Measurement?

Early geometric tools included simple things like a straightedge, compass, divider, and set-square. More recently, modern geometric measurement tools have grown to include sensors, laser alignment tools, and inclinometers or clinometers.

A clinometer lets users accurately measure angular deviation on flat surfaces and shafts and along edges, borders, and vertical shafts.

Why Surface Flatness and Level are Critical to Laser Shaft Alignment?

Level and flat are sometimes thought to be the same thing, but they are not. Flatness is associated with the topography, smoothness, or curving of a machine or surface. At the same time, level describes how a surface, device, or machinery system is situated in relationship to the earth's gravity.

Flatness and level are essential to shaft alignment because when a machine is not flat or level, it can cause shaft misalignment. For instance, the base on which a new device is placed might not be flat, or the actual machine bottom could contain a burr. If the machine isn't level when installed, it can cause soft foot . A precision laser shaft alignment system can help catch these issues.

What Tools are Used When Making a Geometric Measurement?

Many different tools are used to take geometric measurements, from simple tools, such as a straightedge or square, to more sophisticated tools, such as precision laser shaft alignment tools.

Training

We offer alignment, vibration & balancing, ultrasound, and reliability training.

Find a course

Fluke Deutschland GmbH

Fluke Deutschland GmbH