- Products and Services

- Alignment Systems for Rotating Machinery

- Shaft Alignment

- Laser Alignment Systems

- OPTALIGN touch

Learn more...

OptAlign Touch – Laser Alignment System

OptAlign Touch delivers unrivaled precision and easy-of-use with cutting edge technology from the old pros in laser alignment, Prüftechnik.

Simplified high-precision alignment: Geared towards standard alignment tasks, ideal for users who need a reliable, straightforward solution for routine alignment jobs..

User-friendly: Features an intuitive touchscreen interface with guided procedures, making complex alignment tasks more accessible to users of different skill levels (WiFi & Bluetooth connected)

Powerful software: OptAlign provides essential analysis tools for standard alignment tasks, focusing on streamlined monitoring, trending, and reporting, along with simplified data-handling

Machine train alignment: 3 machines

Measurement modes: The system offers various measurement modes, including single-point, multi-point, and continuous sweep, to accommodate different alignment scenarios.

Soft foot detection: OptAlign helps identify and correct soft foot conditions, a critical step for ensuring proper machine alignment and operation.

Active Situational Intelligence (ASI): This feature automatically adjusts to the alignment situation, providing real-time feedback and guidance to enhance the alignment process.

Live Move: OptAlign offers Live Move functionality in both vertical and horizontal planes, enabling real-time adjustments and immediate feedback during the alignment process.

Pre-defined machine templates: The system includes a variety of pre-defined machine templates, streamlining the setup process for common types of machinery.

Thermal growth compensation: Allows users to input target values for thermal growth, ensuring that machines are aligned correctly at all operating temperatures.

Intelligent reporting: Generates detailed reports that document the alignment process, results, and recommendations, aiding in compliance and maintenance planning.

Robust hardware: Designed with IP65 industrial-grade materials, making it suitable for harsh working environments and ensuring durability and longevity.

Fluke Reliability extended warranty: Gain peace of mind, convenience, device accuracy, and savings on service costs via 2 – 5 year mfg. warranty, 3 free calibrations, and 15% discount on repairs.

Get Product Information

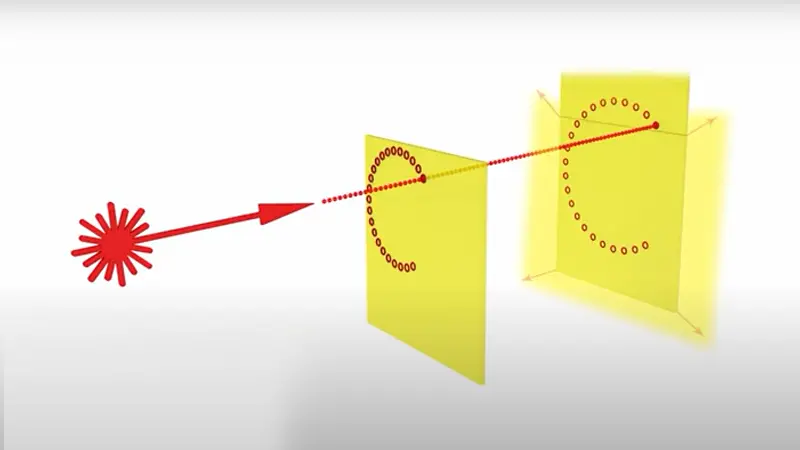

sensALIGN technology

The sensALIGN Series technology is based on the inherent PRUFTECHNIK single laser technology providing highly precise measurement results and easy mounting and measuring in the field. sensALIGN 5 sensors include two HD large position-sensitive detectors (PSD) and MEMS inclinometers. Combined with the detector extension capability (InfiniRange), it is always possible to measure and document the initial alignment condition; no matter how big is the misalignment. Furthermore, this technology allows the simultaneous monitoring of the machine corrections in vertical and horizontal directions, starting from any angular position where the sensor comes to stop.

Download more information for free

Case studies

Technical Data

Manuals

Brochures

Certificates

Customer FAQ

What's new?

touch device Firmware Version 2.5

ANSI tolerances available for Short flex and Spacer coupling types

Resolution available in both 2DP and 3DP (Metric)

Report print preview

Report new section: Measurement equipment serial number and due calibration date

Tolerance screen accessible directly from Results view

Context sensitive help ‘?’ button directly accessible within main workflow screens

"Add feet" button available in stationary machine properties

Please note: touch device firmware version 2.5 strictly requires ARC 4.0 software version 2.5 to communicate.

How to upgrade your firmware?

touch device - ALI 50.200 upgrade procedure

Please ensure the touch device is charged or has at least 50% battery capacity.

Unzip file to empty PRUFTECHNIK USB memory stick. Firmware is stored in "touch" folder.

Switch on the touch device. Wait for Home screen to appear.

Connect USB memory stick to the touch device USB port. New firmware copied from USB memory stick to the touch device.

After approximately 1 minute on-screen message box appears stating new upgrade firmware found. Tap green tick button to start upgrade. Remove USB memory stick from the touch device.

The touch device restarts and firmware upgrade begins.

After completion of firmware upgrade the touch device restarts and finishes in Home screen.

Device Viewer

The Device Viewer software is used to demonstrate the operation of the instrument on a PC or Laptop.

Software needed?

What our customers say?

PRUFTECHNIK provide services for vibration reduction, geometrical precision, innovative testing technologies, and knowledge transfer to make your production equipment and plants more performant and efficient.

Easy to use and extreme alignment precision. Optalign is just awesome...

Fluke Deutschland GmbH

Fluke Deutschland GmbH