EDDY CURRENT TESTING

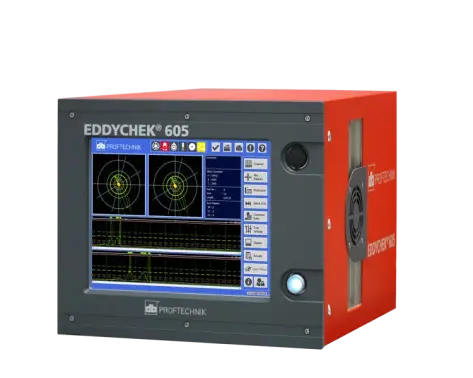

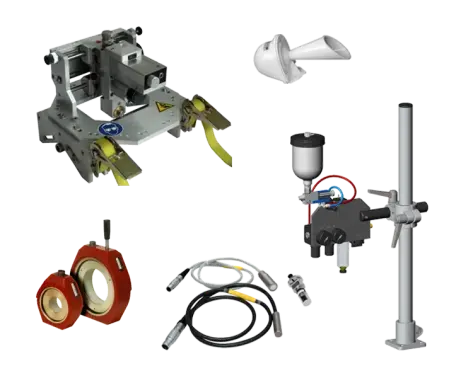

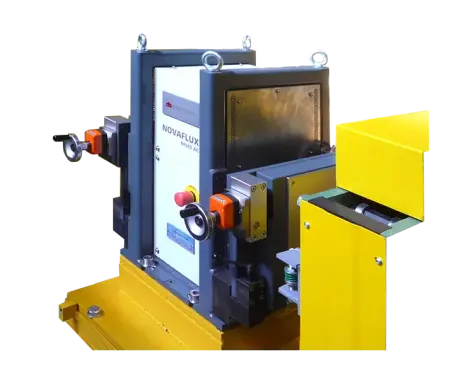

Nondestructive testing systems from Prüftechnik ensure that manufacturers of semi-finished products and their customers obtain the best possible quality. Our eddy current testing systems and sensors provide quality assurance and process control and help you guarantee the security of your investment.

EDDY CURRENT TESTING FAQ

An eddy current is a current initiated in a conductor that reacts to a changing magnetic field. They flow in closed loops within conductors, in planes perpendicular to the magnetic field and get their name because they look like eddies such as those that occur in whirlpools. They’re generally used to measure shaft displacement. They are used widely in several industries, including manufacturing and aerospace where eddy current testing inspections are required to reduce safety-related or quality-related problems, such as in thin metal areas.

What is eddy current testing?

Eddy current testing is built on the interaction between a magnetic field source and the test material. This interaction induces eddy currents in the test piece. Eddie current devices, such as an eddy current system or sensor, can detect the presence of tiny cracks by monitoring changes in the eddy current flow.

Eddy-current systems and sensors are non-contact, non-destructive testing devices that measure displacement using the principles of eddy currents.

How do you choose the proper eddy current testing tool?

The eddy current testing tool you choose depends on the complexity of the needed test. Eddy testing devices range from complex high-performance systems to budget-friendly basic systems. The number of channels and testing points required will affect the cost of the tools. More complex testing usually requires more channels and more test positions.

Fluke Deutschland GmbH

Fluke Deutschland GmbH