What is adaptive alignment?

Adaptive alignment is the next generation of laser alignment systems – developed by PRUFTECHNIK, the inventors of laser shaft alignment who continue to innovate in the field. It is a combination of software and hardware innovations enabling maintenance teams to address a wide variety of alignment challenges that basic laser alignment systems cannot handle.

Adaptive alignment systems can adjust to:

Adaptive alignment systems eliminate “guesstimates,” wasted effort, and time-consuming rework that occur with basic laser alignment systems.

What products do we have in the adaptive alignment category?

ROTALIGN Touch

ROTALIGN Touch EX

OPTALIGN Touch

SHAFTALIGN Touch

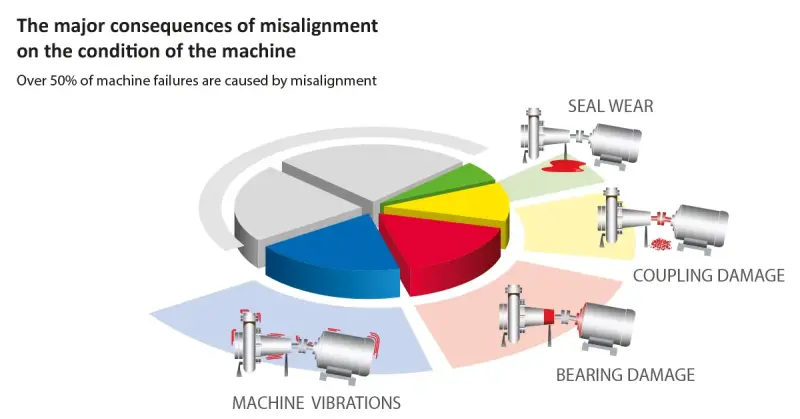

Why do I need an adaptive alignment system?

Because you don’t want to spend good money on an alignment system that either can’t handle all your alignment tasks or can’t grow with your needs. With today’s wide range of asset types, alignment situations, and team skills, you can’t attempt to get by with a basic, limited system. While these systems are sometimes cheaper, they yield false savings. What you might save in the cost of other systems, you will pay many times over in time-consuming rework and lower precision.

What makes adaptive alignment products unique?

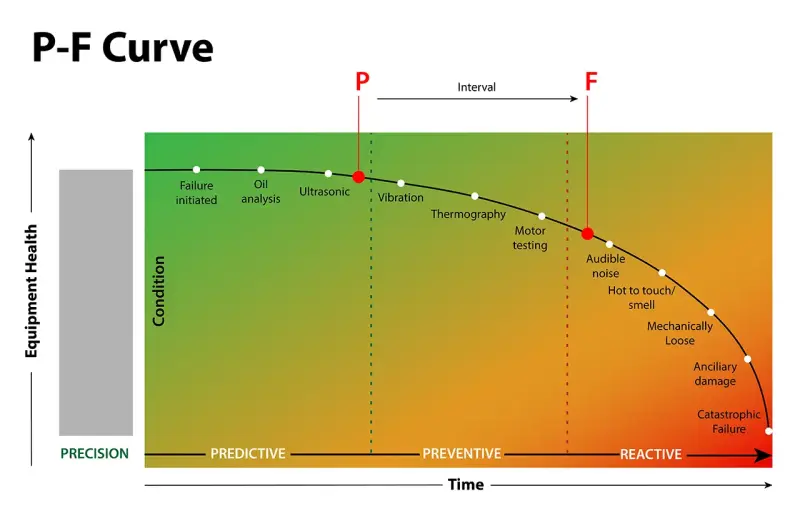

Two innovations – Single-Laser Technology and Active Situational Intelligence – differentiate adaptive alignment products from their basic predecessors. Together, they deliver the “magic” that enables PRUFTECHNIK alignment products to automatically adapt – in real time, as alignment jobs are finished – to the asset, the situation, and the technician.

What are the benefits of adaptive alignment?

Besides their ability to handle all alignment tasks, from simple everyday jobs to more complex challenges, adaptive alignment products deliver:

New levels of speed and accuracy

Greater ability to restore assets to peak performance

Support for a broader range of critical rotating asset types

Unlocked team capacity by enabling every technician to work faster, archive highly precise alignment results, and collaborate instantly with experts when necessary

I only have simple, straightforward alignment tasks - why do I need an adaptive alignment system?

With an adaptive alignment system, your team will complete jobs faster and with greater precision – even for everyday alignment tasks. That’s because Active Situational Intelligence (ASI) is always at work, correcting for common human errors and environmental problems without slowing the job down.

Adaptive alignment systems enable you to entrust alignment jobs to technicians with less experience, without compromising the results. ASI is there to help them, and with cloud collaboration, they can share measurements and get advice from more senior technicians without having to leave the asset.

Basic systems do not possess these qualities, and therefore cannot deliver such benefits.

But you also need to consider whether all your alignment tasks are straightforward – and will always be. Often plants have special situations, such as a few unusual machine configurations, gross misalignments, tight clearances, or environmental factors that come into play. In those cases, a basic alignment system runs into difficulties, and the time and cost for the alignment job escalate. Often, what maintenance leaders save with a cheaper system in the short term, they lose in manual efforts and rework over time.

Why is an adaptive alignment system better than other systems?

Adaptive alignment systems enable users to efficiently handle a wide range of alignment challenges – from simple to complex scenarios – avoiding the rework that comes with more basic systems. Furthermore, ease of use is strengthened in the many situations where basic laser alignment systems struggle. Adaptive alignment systems eliminate human error while delivering new levels of accuracy and speed. This next generation in laser shaft alignment is made possible by two must-have underlying innovations: Single-Laser Technology and Active Situational Intelligence.

They work faster, eliminate errors, and unlock team capacity, enabling maintenance and reliability teams to ensure maximum operational life and efficiency for critical assets entrusted to their care.