HANDHELD VIBRATION ANALYZERS

Pruftechnik is the industry leader in vibration analyzers, designing innovative handheld vibration analysis equipment that helps prevent downtime and strengthen reliability since 1972. Pruftechnik handheld vibration analyzers are the ultimate tools for preventing unscheduled downtime, minimizing failures, and evolving your maintenance practices into condition-based and predictive maintenance.

REDUCE UNPLANNED DOWNTIME

CATCH MACHINE FAULTS

KEYS TO VIBRATION ANALYZER SUCCESS

Vibration Analysis and field balancing FAQ

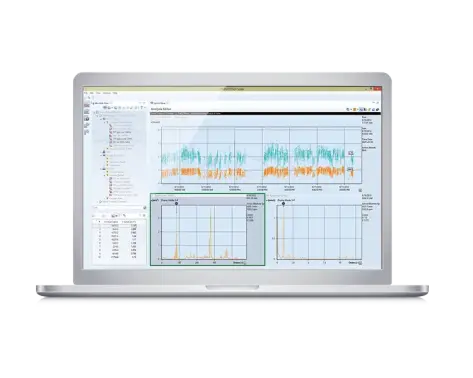

Pruftechnik handheld vibration analyzers like the VibXpert 2 are high-precision FFT solutions for troubleshooting and machine health insights. Data collection is quick and easy: the VibXpert 2 is a true 2-channel data collector and signal analyzer designed to simplify measurement.

Pruftechnik software is easy-to-use, doesn’t penalize you with monthly fees, and offers unlimited and free updates. And when it comes to data security, you can trust Pruftechnik’s best-in-class cloud security to safeguard your data and defend against breaches.

For all-in-one vibration measurement, vibration experts also love the VibScanner2 vibration analysis tool. Measurement is four times shorter than the industry standard, operation in easy, and users can perform comprehensive machine data collection with the push of a button.

Pruftechnik handheld vibration analyzers are the ultimate tools for preventing unscheduled downtime, minimizing failures, and evolving your maintenance practices into condition-based and predictive maintenance.

What are Vibration Analyzers?

Technicians use vibration analyzers to measure, store, and analyze the vibrations produced by industrial equipment or installations.

Rotating machines – like compressors, pumps, and fans – all vibrate while in operation. Every machine produces its own, baseline level of vibration, or vibration “signature.”

Changes in vibration levels or vibration frequency can mean that your asset is developing a new defect. Over time, excessive vibration can damage machinery and create dangerous conditions on your floor. But changes in vibration patterns can also indicate underlying issues like misalignment, imbalance, and bearing faults.

Vibration analyzers measure changes in vibration frequency, displacement, and acceleration. They store vibration data so that you can easily spot patterns and changes over time.

Some vibration analyzers can also use vibration data to diagnose problems in the field. In many cases, good analyzers can also guide technicians through the process of the machine fault.

How Do Vibration Analyzers Work?

Vibration analyzers are complex tools. They’re both measuring and analysis tools, allowing them to both gather data and analyze it.

Data Collection

Vibration analyzers use a built-in piezoelectric accelerometer to measure vibration levels on industrial equipment, in buildings, on bridges, or on other installations.

The accelerometer captures vibration data and converts into an electrical signal. Depending on the tool, it may record that data as a time waveform or an FFT. You’ll see the data displayed on the vibration analyzer’s screen.

Depending on the tool, it may also make the data available remotely, so that your teams can access it on their smartphones or tablets when they’re off-site.

Data Analysis

Modern vibration analyzers don’t just collect and organize data, though. They take the data and analyze it on-screen, so that technicians can see exactly where the problem is and how to fix it.

In some cases, the tools color-code the key data and create a step-by-step guide to correcting machine faults.

For example, if a particular asset is unbalanced, a high-quality vibration analyzer can provide detailed instructions on fixing the imbalance. Once the repair is done, the tool can also check the new measurements to verify that the technician has, in fact, repaired the problem correctly.

Why Are Vibration Analyzers Important?

Many operations today are working with a limited maintenance force. At the same time, the typical plant is trying to follow a tight production schedule, with no room for downtime or drops in productivity.

Vibration analyzers can make sure that your assets stay up and running for as long as possible. By catching machine faults early, they ensure that you avoid unnecessary downtime. You also avoid excess energy consumption and slowdowns that come from unbalanced or misaligned equipment.

The earlier you identify defects, the easier it is to schedule repairs at convenient times. And of course, the sooner you address machine problems, the lower your repair costs will be.

Many plants today don’t have a deep bench of maintenance experts. It’s a good idea to look for tools that can provide guidance and even help train newer employees.

What to Look for in a Vibration Analyzer

The best vibration analyzers are accurate, precise, and easy to use.

Tools like the VibXpert II are intuitive and user-friendly. Even employees with very little technical knowledge can use it right out of the box.

The tool is thorough and leaves nothing up to guesswork. It measures vibration levels in 3 axes – horizontal, vertical, and axial, taking the operator through the steps needed to measure correctly.

If the asset is vibrating excessively, the VibXpert II displays an alert, explaining exactly where the problem lies.

Then, the tool’s display walks the user through a step-by-step process to fix the problem. Once the technicians has corrected the imbalance, or the misalignment, VibXpert II can check again to make sure that the issue is totally resolved.

The result? Potential problems get nipped in the bud, all without bringing your operation to a grinding halt.

What is vibration analysis and How Does it Work?

Vibration analysis makes it possible to pinpoint abnormal changes in machinery vibration signatures. All equipment vibrates to a certain extent, but changes in the baseline vibration pattern can indicate a problem is developing, like imbalance, looseness, misalignment, and bearing wear. Excess vibration can also lead to premature component wear and a shorter asset life. That’s why many maintenance teams use vibration monitoring and analysis to proactively detect problems early, so they can be resolved before they get worse.

One of the most common vibration measurement methods for this analysis is using an accelerometer vibration sensor mounted directly on rotating equipment. Accelerometers here work by converting vibrations into an electrical signal. These devices measure changes in the amplitude, frequency, and intensity of an asset’s vibration levels.

Collecting vibration data over time makes it possible for maintenance teams to compare measurements, spot patterns, and quickly pinpoint abnormalities. When failure mode patterns emerge, they can identify potential faults well before they occur.

Using Industrial Internet of Things (IioT) technology, vibration sensors can connect to software that helps maintenance teams make sense of the data collected and determine the most effective corrective actions. Software analytics can track and trend this vibration data over time, so maintenance teams can make data-driven decisions and focus their time and energy in the right place.

How does vibration analysis work?

Vibration analysis measures machine or component movement (vibration). As the piece moves back and forth (vibrates) from one point to the other point repeatedly (cycles), vibration analysis looks at how rapidly (frequency) how far (amplitude), and at what speed (acceleration) the movement occurs.

The importance of vibration analysis

Vibration analysis is a valuable tool that gives maintenance teams a better understanding of asset health and performance, and ultimately helps them make data-driven decisions about their equipment.

For critical assets, maintenance teams can use wireless sensors to monitor equipment around the clock, saving time on manual readings while giving an accurate and up-to-date picture of asset health. This capability is key to a predictive maintenance approach, where problems can be identified and resolved before they lead to unplanned downtime and production stoppages.

What are the benefits of adding vibration analysis tools and field balancing tools to your preventive maintenance strategies?

Vibration analysis tools open the door to predictive maintenance (PdM) strategies. PdM uses data collected by wireless remote condition monitoring sensors to analyze equipment condition and helps maintenance professionals predict when maintenance should be performed.

How is Vibration Analysis Conducted?

Vibration analysis starts with understanding the asset’s normal vibration levels at its various states, including normal operation, startup, and shutdown. An asset’s signature vibration pattern is essentially a fingerprint of how it normally behaves. With this baseline established, you can create thresholds for acceptable vibration levels vs. abnormal vibration levels.

Once baseline and thresholds are defined, the next step is to translate the raw vibration data into a model that can be analyzed, usually a waveform diagram, showing vibration changes over time. From there, analyze the data, looking specifically at synchronous peaks. These are the high points in your vibration data that repeat at expected times, like every time the motor rotates. Peaks like this are totally normal and aren’t a cause for concern, but usually high spikes or peaks that happen at an unexpected time can indicate a problem worth investigating.

What is Vibration Monitoring?

Vibration monitoring measures the amplitude, frequency, or intensity of the vibrations emitted by any rotating piece of machinery, including motors, fans, pumps, and more. Every piece of rotating equipment has its own vibration signature: a baseline healthy vibration pattern. Variations from this baseline are often the first sign of a problem.

Maintenance teams can use either handheld vibration meters or vibration sensors mounted to key points on the machine to measure the machine’s vibrations over time. If the vibration pattern changes, it may be because there is a fault in the machine. Vibration monitoring can pick up on even minor defects, giving maintenance teams plenty of time to make repairs before the problem gets worse.

Vibration monitoring sensors can measure vibrations continuously and alert maintenance teams to changes in an asset’s condition in real-time. Wireless sensors can send that data straight to a mobile device to ensure prompt attention. A data analytics software can also track and analyze vibration data over time and make smart predictions about asset health, performance, and future maintenance requirements.

What are the Benefits of Vibration Monitoring and Vibration Analysis?

Vibration monitoring helps maintenance and reliability teams identify potential machine faults and plan accordingly. It also makes it possible for maintenance teams to be more proactive, schedule maintenance activities based on asset condition, and predict and prevent breakdowns. Vibration monitoring can detect faults 12 to 18 months before failure, making it an integral part of a successful condition-based maintenance program.

Fluke Reliability Solutions

Fluke Reliability Solutions