How to securely and efficiently monitor roller bearings

Find here the solution to monitor bearings’ conditions efficiently on a wind turbine.

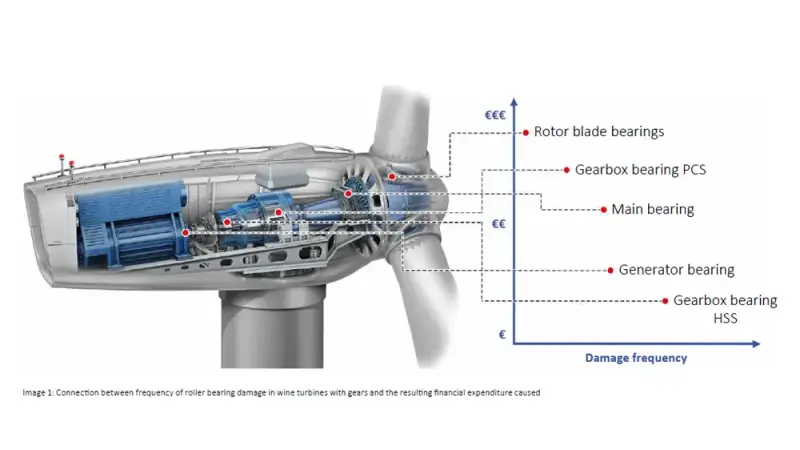

As highly-stressed components, roller bearings in the drive train of wind turbines are subject to countless influences from “manufacture, assembly and operation.” Bearing-specific changes in state can be detected at a relatively early stage through structure-borne soundbased traditional methods of roller bearing monitoring and diagnostics.

In connection with the monitoring of larger fleets, data-driven procedures help to prioritize irregularities by extracting characteristics from measured overall readings and diagnostic characteristics and assigning them to defined roller bearing conditions based on standards and guidelines. The prerequisite for these type of applications, however, are powerful and continuously measuring CMs, which work as edge devices and support IIOT-relevant protocols, such as MQTT.

Download the case studyHow can we help you?

Please send us your inquiry and our experts will get back to you shortly.

Fluke Deutschland GmbH

Fluke Deutschland GmbH