Why Prüftechnik is the mining industry’s go-to brand

Miners work in some of the most demanding conditions of any industry, and they require maintenance tools and systems that are rugged, durable, safe to use, and extremely dependable. After all, unscheduled downtime can set a mining company back up to $100,000 per day.

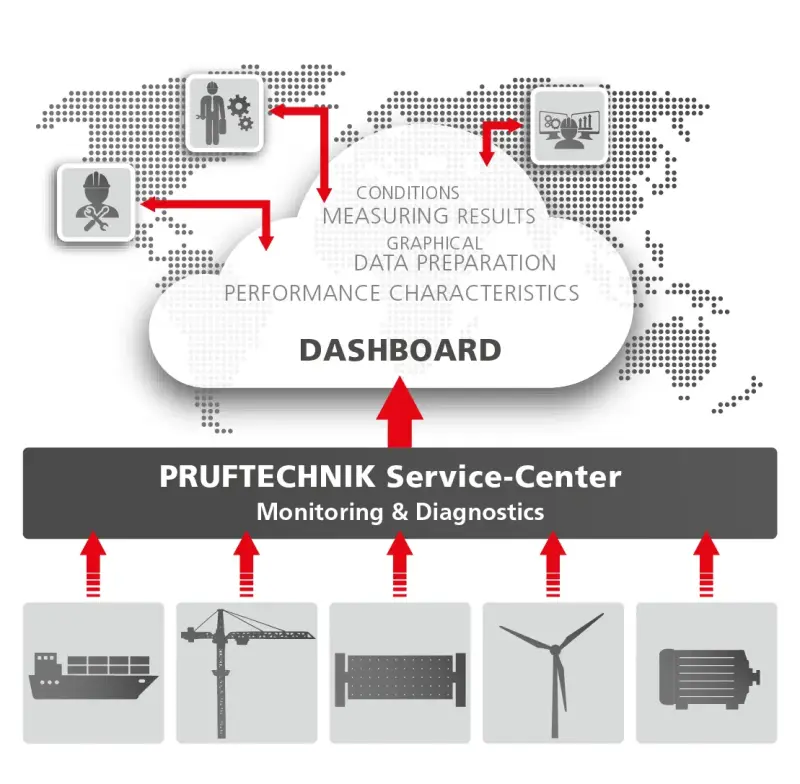

Prüftechnik, part of Fluke Reliability, provides mining companies the world’s most comprehensive portfolio of tools, software, and services for their maintenance and reliability requirements. We supply industry-leading laser shaft alignment tools, innovative vibration sensors, data collection and condition monitoring systems, and a powerful CMMS platform—all backed by award-winning training and support.

Our unrivaled RotAlign Touch and other Adaptive Alignment laser systems from Prüftechnik keep your critical assets aligned and in peak condition. Prüftechnik online condition monitoring systems track machine vibration and other relevant machine condition parameters around the clock, enabling you to effectively predict critical machine and equipment deficiencies and conduct data driven repairs.

Learn more about how Fluke Reliability solutions help you digitalize, automate, streamline and consolidate maintenance-related operations.

Facts and Figures

Mine assets are running

24/7 Many mines run assets around the clock, meaning unplanned downtime is costly to production and revenues

Save money

25x ROI Return on Investment experienced by one Brazilian mining client

692.000.000

Worldwide mining revenue in 2019 (U.S. dollars)

What we do

Find out more ...

Increase Uptime

Our industry solutions increase asset and plant availability.

Schedule a free product demo

Please leave us a message and we will contact you to schedule a free product demo at your premises.

Free product demo

Fluke Deutschland GmbH

Fluke Deutschland GmbH