This is how condition monitoring works – act instead of react!

We care about your assets - Vibration analysis is our business

Condition monitoring means that every machine is regularly subjected to a ‘health check’ – normally with a vibration inspection: in the simplest case, the measurement instrument used to perform this check provides a numerical value that can be compared with a standard value to indicate the machine’s state,

Good - OK - Bad.

Production-critical machines as well as less critical machines, large and small industrial plants, discrete and distributed plant locations, operators and service providers: each require their own special monitoring strategy with customized condition monitoring solutions.

Condition Monitoring

Vibration Analysis, Balancing and online Condition Monitoring

We are the experts

Predictive maintenance tools for vibration analysis can help prevent machine failure and avoid costly production downtime.

Our vibration analysis tools are used for condition monitoring on rotating equipment to help detect early component wear and damage. Vibration analysis and balancing are integral parts of any condition-based and predictive maintenance program.

Online Condition Monitoring systems track machine vibration and other relevant machine condition parameters around the clock so you can trend and analyze data. Entire plant sections or only critical machines can be monitored with online systems to optimize plant availability. The Fluke Reliability solutions from Pruftechnik and Fluke below alert you to abnormal readings requiring action and help you extend asset life.

Key benefits of condition monitoring

Low efficiency without condition monitoring

Strong vibrations, heat, and noise

Rotor imbalance

Bearing damage and failure

Premature wear of components such as gears and/or bearings

Loss-of-production and unplanned downtime

Maximum performance with condition monitoring

Early detection of machine problems

Eliminate the causes of failure

Reduce vibrations and heat

Higher machine availability and system safety

Reduce operating and maintenance costs

Increase in profit by

Early damage detection

Optimum planning of repair work

Increasing machine availability

Reducing spare parts storage costs

Avoiding unplanned loss of production

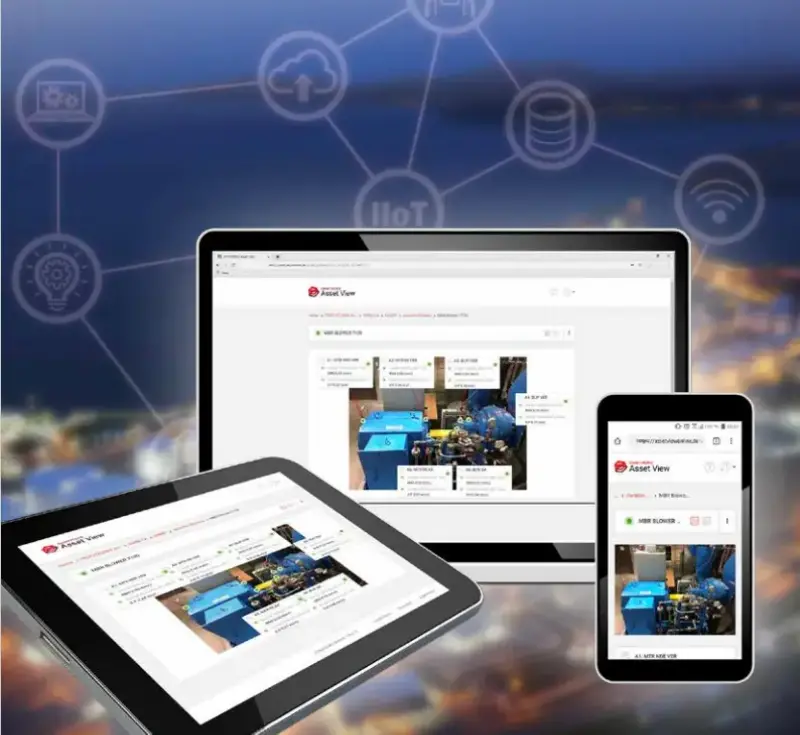

Condition Monitoring in Industry 4.0

Do you speak “IIoT”? We do!

The “Industrial Internet of Things”, IIoT for short, massively changes the maintenance of the present and the future. PRUFTECHNIK already has the right solutions for the future!

All kinds of sensors control and influence machine behavior in such a way that human interventions are often no longer necessary. Asset controls are stored on external servers, in "the cloud", and connected to the sensor measurement data. Intelligent software enables asset optimization for maximum productivity based on the sensor data. At the same time, the machine data can be called up at any time from anywhere in the world via Internet browser.

Global data availability

Reduced data transfer volume

Optimized machine efficienc

Fortive MENA

Fortive MENA