Alignment seminar Level2 Alignment with sensALIGN S7 On Demand

Alignment with S7 alignment systems RotAlign Ultra “iS” and RotAlign Touch

COURSE CONTENT

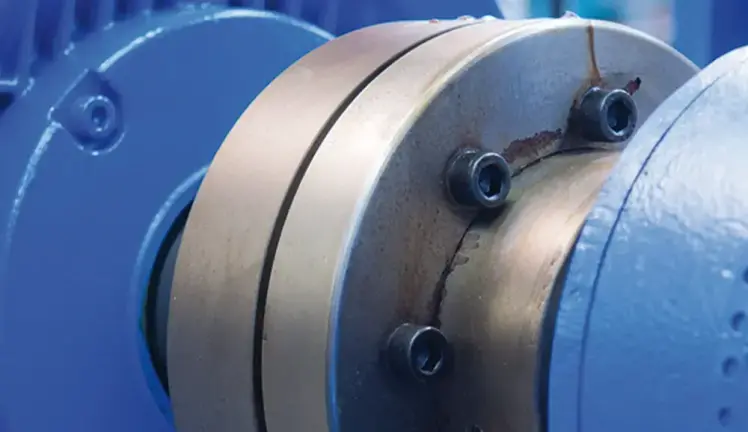

Fundamentals of shaft alignment

• Alignment – why?

• Alignment – what is it?

Prerequisites and preparations for optimal machine alignment

The sensAlign measuring principles

• Technical description, laser, sensor, computer

• Configuration of the RotAlign computer

Practical exercises

Laser/sensor assembly / measurements in continuous measuring mode / reproducibility of measurements and evaluation in the measurement table / results evaluation according to Pruftechnik or user-defined tolerances / saving a measurement and creating a report as a PDF file / soft foot inspection / aligning the machine with the “move function”

Theory-based exercises/special cases

Alignment of vertical machines / alignment of machines equipped with plain bearings / alignment of machine trains / alignment of cardan shafts / alignment of uncoupled machines / alignment of machines with defaults/thermal growth / live trend – displacement measurement (RotAlign Ultra iS and RotAlign touch users)

Creating and sending work orders to a mobile device via the cloud (only ROTALIGN Touch users)

Editing and managing alignment results using the Alignment Reliability Center 4.0 or Alignment Center PC software

DURATION

2 days

Start/End

Day 1: 9:00 AM - 5:00 PM

Day 2: 8:00 AM - 4:00 PM

PARTICIPANTS

Maximum 8

TARGET AUDIENCE

Engineers, technicians, foremen and skilled workers from the field of plant monitoring and condition-based plant maintenance, who are responsible for arranging alignment work or are tasked with such work themselves.*

Fortive MENA

Fortive MENA