ONLINE CONDITION MONITORING

Online Condition Monitoring systems track machine vibration and other relevant machine condition parameters around the clock so you can trend and analyze data. Entire plant sections or only critical machines can be monitored with online systems to optimize plant availability. The Fluke Reliability solutions from Pruftechnik and Fluke below alert you to abnormal readings requiring action and help you extend asset life.

Condition Monitoring FAQ

Condition monitoring (CM) uses Industrial Internet of Things (IIoT) sensors and other tools to continuously track machine health and measure vibration levels, temperature, or other measurements. When something changes in the machine, these tools trigger an immediate alert notification, letting maintenance teams act before the asset potentially fails.

Vibration sensors are particularly important condition monitoring tools for identifying the four most common rotating machinery faults : imbalance, looseness, bearing damage, and misalignment.

Condition monitoring using vibration sensors is a scalable way to monitor and gather data from a broad portfolio of production critical and semi-critical assets.

Machine condition monitoring opens the door to predictive maintenance strategies like condition-based maintenance (CBM) . Condition-based maintenance studies the health of specific machines and the likelihood of their failures, then uses that real-world data to make maintenance decisions. That stands in contrast to preventive maintenance , or calendar-based maintenance, where work is performed whether it’s necessary or not.

What is a Condition Monitoring System?

A condition monitoring system is the key to keeping your machinery up and running for longer.

Condition monitoring uses wireless sensors with software analytics to keep tabs on the health of your rotating equipment. The system is designed to catch the first signs of a new machine fault, so that your technicians can get in and repair the problem early.

The sooner you catch defects, the easier it is to fix the issue. That means you’ll see lower maintenance costs, and more uptime.

What are the Main Components of a Condition Monitoring System?

A good condition monitoring system is the heart of any predictive maintenance program.

Condition monitoring systems do much more than just collect data about your equipment. They also analyze that data and help your teams make smart decisions.

Every system is different, but most condition monitoring systems have four main components: sensors; handheld tools; software; and services.

Sensors

Wireless sensors mount directly on your equipment, where they collect data on vibration emissions, temperature, and other indicators of health. The best sensors can pick up on machine faults months before the faults become serious enough to cause a breakdown.

Sensors stream that data to your computing system, so that it can be analyzed for signs of trouble. Analytic software can spot patterns and alert your team at the first sign that your assets are developing a problem.

The Fluke 3563 Analysis vibration sensor system combines a high-frequency wireless vibration and temperature sensor with a data analytics program. The system is easy to use right out of the box. Its dashboard includes a summary of data on all the assets being monitored. The system also sends alerts whenever your assets cross a threshold and show signs of defects.

The Fluke 3563 also comes with built-in support from the Fluke team of vibration experts. Users have access to training and mentoring, as well as assistance with everything from installation to monitoring.

Sensors can measure more than just vibration and temperature. Depending on your industry, you may need to include power monitoring , oil analysis, and ultrasound sensors in your condition monitoring system.

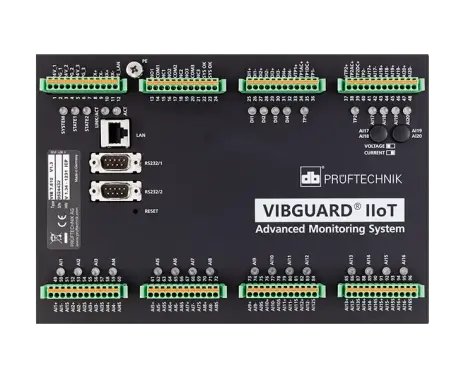

Vibguard IIoT is a comprehensive condition monitoring system designed for machine parks. Vibguard uses up to 20 parallel channels to monitor just about every kind of signal input, including vibration levels, tacho pulse, temperature, and torque.

VIBGUARD automatically measures and processes data like time signal, characteristic value, FFT spectrum, and torque in near real-time. The system’s speed makes it a natural choice for monitoring equipment with short operating cycles or dynamic processes.

Handheld Tools

Handheld vibration monitoring tools can perform route-based data collection or help technicians troubleshoot whenever a problem comes up.

They don’t collect data continuously, the way wireless sensors do. But handheld tools are invaluable for carrying out inspections in the field, or for getting to the bottom of a problem in the plant. Some handheld tools also store data, making it easier to identify patterns in your asset’s vibration emissions. Some handheld tools also have displays that guide technicians through fixing balance issues.

The Fluke 810 can identify common machine faults like misalignment, unbalance, looseness, and bearing issues. The tool’s display is easy to read and labels faults in clear English, according to severity level. It also guides technicians on fixing the issue.

Other handheld tools, like the VibScanner 2 EX , are designed to work in hazardous areas. VibScanner EX is explosion protected and shock proof. It works quickly and accurately, and technicians can operate it while wearing protective gloves. Its graphic display is easy to read and understand, even for employees who don’t have a strong technical background.

Data is not enough on its own. A solid condition monitoring system also needs the tools to analyze that data. That’s why software analytics are so important.

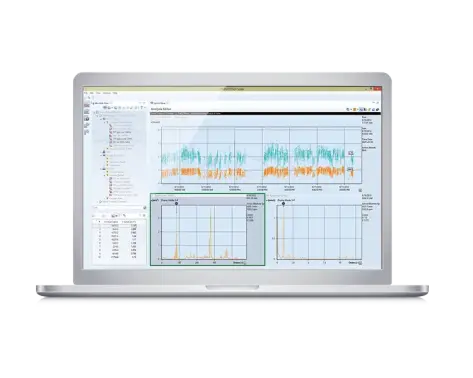

The Fluke LIVE-Asset Portal software organizes and analyzes data so that teams can always spot new and developing faults in their rotating machinery. The software identifies the root causes of defects and issues alerts whenever machines exceed certain parameters. It also guides users to the best next-step actions.

OmniTrend wraps all the functions you need into one, central location. Reporting, diagnostics, archiving, and data management are all available. Analyze data from handheld tools or from wireless sensors. The software platform is easy to use. The system automatically stores historic data and uses it to make in-depth diagnostics about your machine health, so that your team knows exactly how to correct issues.

Services

Many plants operate with a labor shortage and may lack the expertise necessary to run a successful condition monitoring program. That’s why services are a key element in any condition monitoring program.

Fluke’s team of condition monitoring experts is available to guide your operation through installation and help with ongoing monitoring. They are also on-hand for troubleshooting, training, and mentoring. The team provides help on either a one-time basis or as part of an ongoing partnership.

What Types of Assets are Typically Covered with a Condition Monitoring System?

Condition monitoring is often associated with rotating machinery. Any motor-driven asset can benefit from a condition monitoring system. Engines, pumps, turbines, blowers, and compressors are all great candidates for condition monitoring.

Vibration and temperature monitors can identify early signs of imbalance, misalignment, and other issues. Ultrasound monitoring can spot leaks in pump and valve systems. Oil particle monitors can find gearbox issues and identify wear and tear on rotating assets. Power monitors can also spot problems in electrical equipment of any kind.

In many cases, vibration and temperature sensors can also monitor buildings, bridges, and industrial sites for signs of faulty construction or other dangers.

How Does Condition Monitoring Work?

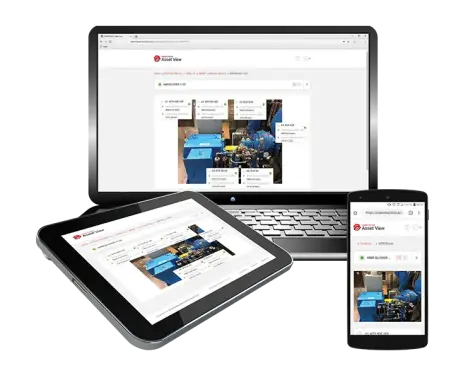

Condition monitoring uses networks of connected sensors, gateways, and software, to collect, process, and analyze machine data. The combined connectivity creates an integrated system that lets maintenance teams collaborate and make decisions from anywhere in what’s called Remote Condition Monitoring .

Remote Condition Monitoring happens when wireless condition monitoring sensors pair with cloud-based software, so technicians and other reliability professionals can access the data remotely using a computer, mobile phone, or laptop.

What is an Example of Condition Monitoring?

Condition monitoring uses sensors and hand-held devices to measure the “vital signs” of your equipment, or key indicators of equipment performance and health. For example, condition monitoring can be used to measure your machinery’s power usage, temperature, vibration frequency, and more. They alert you to machine faults early, so that you can make repairs and avoid unplanned downtime.

One of the most common forms of condition monitoring is vibration monitoring . This is because a change in vibration patterns is often one of the first indicators of equipment failure. In fact, vibration monitors can identify defects in your rotating machinery months before the faults turn into a serious problem.

However, there are many different types of condition monitoring tools in addition to vibration monitoring that can help you get ahead of maintenance problems. Power monitors, for example, are valuable condition monitoring tools for tracking the health of your electric devices. Power monitors measure changes in assets’ energy consumption. They also measure fluctuations in current, voltage, and frequency. Changes in these areas can point to safety issues that your maintenance teams need to address quickly. They can also indicate significant wear and tear on parts, meaning that you need to replace or repair a component.

Meanwhile, temperature monitors can alert you to unexpected changes in equipment temperature so you can quickly identify and resolve issues like equipment overheating.

Why is Condition Monitoring Important?

Condition monitoring is a key component of any predictive maintenance strategy. Condition monitoring helps reduce unplanned downtime by enabling you catch problems before they lead to failure. This further reduces maintenance costs and increases machine availability and productivity.

In the past, condition monitoring was expensive and was primarily used on large-scale equipment like HVACs. Today, however, the technology is affordable even the leanest budgets. With the costs saved by reduced maintenance and increased uptime, condition monitoring quickly pays for itself.

Condition monitoring is also turning into a necessity. Most operations have more complex equipment than in the past, all while facing increased competition and higher customer expectations. Because of this, it’s more important than ever to avoid any breakdowns that reduce productivity, or worse, delay production and erode customer confidence and loyalty. In contrast, operations with a robust condition monitoring program can not only get ahead of these issues, but also stay ahead of the competition.

What are the Different Modalities in Condition Monitoring?

Condition monitoring systems are adaptable. Depending on your industry, you will need to monitor your machinery for different issues.

Vibration Monitors

Vibration monitoring is one of the best ways to spot defects in rotating machinery. Changes in vibration levels can indicate unbalance, looseness, misalignment, and bearing faults. A vibration monitoring system can identify faults long before they get serious enough to cause a breakdown.

Power Monitors

Power monitoring identifies problems in electrical devices. Changes in current, voltage, frequency, and energy consumption can indicate excess wear and tear on your equipment. Excess load can do major damage to your assets.

Wireless power monitors can stream data to tablets or other devices, so that your team can collect data and make decisions from a safe distance.

Oil Monitors

Oil particle counters look for impurities in your oil that could indicate problems with your filters. Impurities in your oil can also indicate premature wear and tear on your assets or component parts.

Monitoring your oil purity will alert your teams to any new faults in your gearboxes and bearings. The sooner you discover these faults, the sooner your maintenance crews can correct them.

Temperature Monitors

Overheating machinery can be a sign on excess friction, boiler leaks, or faulty electrical wiring. Monitoring the temperature of your assets and components means that you’ll always catch early signs on faults.

Fluke’s vibration sensors are equipped with temperature monitors too. Tracking the heat and vibration levels at the same time means that you won’t miss any developing faults.

Ultrasound Sensors

Ultrasound technology can find even tiny leaks in a pump and valve system. The sensors can identify stuck valves, cavitation, and friction in the system long before it becomes serious.

Like other monitors, ultrasound sensors work well with software that can track historic data and analyze patterns in your asset function and health.

Benefits of Remote Condition Monitoring

Remote Condition Monitoring lets maintenance teams prioritize and optimize their maintenance schedules based on asset health. Wireless and/or wired sensors placed on machinery can monitor asset health continuously, and if conditions change, an email is automatically sent to a designated maintenance team member. Armed with Remote Condition Monitoring, teams can make data-based decisions.

Remote Condition Monitoring Benefits:

• Early detection of machine problems

• Quick, data-based decisions

• Moves maintenance teams to condition-based maintenance

• Improves maintenance planning to prevent downtime

• Reduces costs tied to maintenance, inventory, and production

• Increases asset lifecycle and ROI

The Fluke 3563 analysis vibration sensor is a powerful condition monitoring tool for finding the most common machine faults.

Screening and Analysis Vibration Sensors

All machines vibrate, but excess vibration can cause irreversible damage to machinery and associated components. Under extreme circumstances, vibration can cause a catastrophic failure that shuts down facilities or stops production.

Maintenance teams often implement a combination of two different styles of vibration sensors. A screening vibration sensor alerts maintenance teams to simple vibration changes. And a vibration analysis sensor allows for closer study of vibration frequencies.

Screening vibration sensors offer an important good/bad look at machine health. Analysis vibration sensors work best for finding the most common faults, determining the fault severity, enabling data analysis, and suggesting next steps.

Constantly screening for changes in machine health and analyzing vibration sensor data is especially critical with rotating machinery.

Utilizing the P-F Curve

A variety of condition monitoring sensors, tools, and techniques are used to track and trend the equipment health, from oil analysis and vibration analysis to ultrasound. The goal of using different conditioning monitoring techniques is to extend equipment lifespan as long as possible. The earlier the fault is caught, the more likely the machinery can be restored to its original state.

The potential failure curve, or P-F curve, portrays a machine’s gradual failure over time. The P-F curve is a valuable tool for deciding which condition monitoring technique (modality) to use based on the machine’s expected problems. If a maintenance professional knows what the earliest sign of trouble looks like for a specific asset, they can start searching for those signs of failure using the right tools.

Each condition monitoring technique provides information about asset performance and the impact of a fault.

Three standard condition monitoring techniques used to detect potential faults:

• Vibration analysis is used in condition monitoring and to detect mechanical faults in rotating equipment. Vibration analysis using a vibration sensor can be applied to a wide range of rotating machinery and reveal signs of imbalance, misalignment, looseness, and bearing failure.

• Infrared thermography detects machinery temperature changes by studying patterns, like increased motor heat or an abnormally low temperature. Thermography can detect shaft misalignment, gearbox issues, and belt problems.

• Ultrasound uses high-frequency waves to monitor and detect machine defects like cavitation, leaks, and parts seating.

Choosing the Right Type of Vibration Sensor

Machine vibration screening and analysis using sensors are vital technology for successfully implementing condition monitoring and predictive maintenance programs . Different types of vibration sensors offer different capabilities, but they typically involve an accelerometer containing a piezoelectric crystal that senses mechanical vibrations inside an asset.

The crystal changes mechanical movement to an electrical signal which is then amplified and transmitted via a cable or wirelessly. Piezoelectric sensors are known for their hardiness which enables them to function in industrial settings.

To choose the most suitable sensors, an organization should determine how they will fit into their existing technology and maintenance and reliability program, including which assets to monitor and why. An excellent way to determine this is by performing an asset criticality analysis.

An asset criticality assessment is an important way to classify production critical equipment and other semi-critical and non-critical machines.

Determine Which Machines Need Monitoring with an Asset Criticality Assessment

An asset criticality assessment helps verify which machines are production critical based on business value and overall operations should they fail. The analysis process helps eliminate assumptions about an asset’s importance and instead relies on empirical data, not guesswork.

During the asset criticality assessment , various stakeholders in the organization work together to determine criteria for ranking the assets (1 to 5). With a diverse group, maintenance teams build consensus and cement the asset criticality assessment outcomes. Once ranked, the machinery is grouped and classified as a star, critical, semi-critical, or non-critical asset.

Remote Condition Monitoring Services

Developing a Remote Condition Monitoring program takes time and effort. Starting with a small pilot program can ease the learning curve. Outside experts can also help with implementation and training.

Fluke Reliability has some of the world’s top experts available to help your team with our Remote Condition Monitoring service. We can help with expert data analysis, sensor configuration, commissioning, and installation, or help with understanding the principles of vibration monitoring and data analytics.

PRUFTECHNIK S.E.A. Pte Ltd.

PRUFTECHNIK S.E.A. Pte Ltd.