LASER SHAFT ALIGNMENT TOOLS

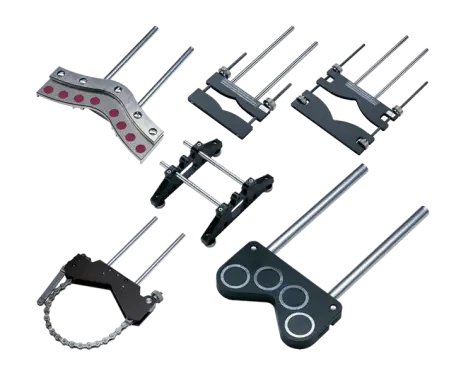

A laser shaft alignment system is the most efficient way to align rotating machinery shafts. Using an adaptive alignment system instead of conventional alignment tools saves you time and money, increases machine availability, prolongs service life and maintenance intervals, and lowers power consumption. Alignment tools from PRUFTECHNIK adapt to virtually any asset, situation, or user skill level.

Adapt to every shaft alignment challenge

● = Included

○ = Optional

|

SYSTEM

SYSTEM

|

ROTALIGN Touch | OPTALIGN Touch | SHAFTALIGN Touch | ROTALIGN Touch EX |

|---|---|---|---|---|

|

|

● | ● | ● | ● |

|

|

● | ● | ● | ● |

|

|

14 machines | 3 machines | 2 machines | 6 machines |

|

|

In-Situ | Standard (Offset) | Standard (Offset) | |

|

|

● | ● | ● | |

|

|

● | |||

|

|

● | |||

|

|

● | |||

|

|

● | ● | ● | |

|

|

● | |||

|

|

● | ● | ● | ● |

|

|

● | ● | ● | ● |

|

|

● | ● | ● | ● |

|

|

● | ● | ● | ● |

|

|

○ | ○ | ● | ● |

|

|

○ | ○ | ● | ● |

|

|

● |

Reduce your maintenance costs

Use our ROI Calculator to simulate your maintenance cost savings with laser alignment.

Schedule a free product demo

Please leave us a message and we will contact you to schedule a free product demo at your premises.

Free product demo

PRUFTECHNIK Inc.

PRUFTECHNIK Inc.